| |

CO2 MIG Wire - Layer Winding |

Characteristics :

"Premier" MIG wires are copper coated solid steel wires suitable for continuous welding for continuous welding for general purpose fabrication on low to medium carbon steels. These wires are manufactured by wet drawing and special coppering process ensuring longer shelf life, easy feed and current pickup. The Random/ Layer Wound wire gives uniform and sound weld metal deposit.

|

Applications :

Mild and structral steel with Tensile Strength up to 55 kg/mm2

|

Classifications :

IS 6419: |

1996 Grade S4 |

AWS A5 18 : |

ER70S-6 |

BS 2901 : |

A-18 |

DN 8559 : |

SG2 |

|

|

Wire Chemistry Composition

Element |

Percent |

|

C |

0.06-0.12 |

|

Si |

0.80-1.15 |

|

Mn |

1.40 to 1.60 |

|

S |

0.025 |

|

P |

0.025 |

|

Mechanical Properties of all weld Metal

| |

Ultimate Tensile Strength Kgf/mm2 |

Yield Strength Kgf/mm2 |

Enlongation % (L=5d) |

Charpy-V Impact value at -29 degree C KGfm |

| Minimum values required |

51 |

42.8 |

22 |

2.80 |

| Typical values |

57.8 |

46.9 |

31 |

6.40 |

|

Welding Data :

Size Dia (mm) |

0.8 |

1.0 |

1.2 |

1.6 |

Welding Amps. |

50-180 |

75-220 |

90-300 |

180-500 |

Welding Position |

Down hand/horizontal/vertical |

Spool Size |

300 mm Od * 50.5 mm ID * 103mm Width |

Net Weight |

12 to 15 Kgs. Per Spool Approximately |

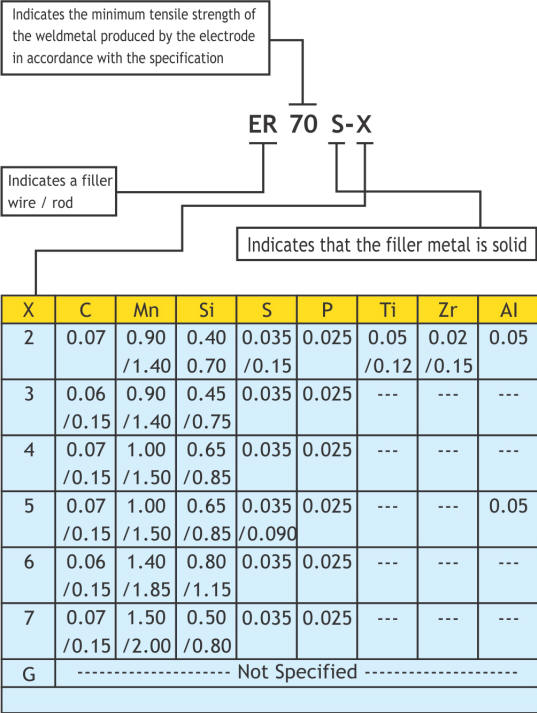

SOLID WIRE

CLASSIFICATION FOR GTAW/GMAW

|

|

|